Overview

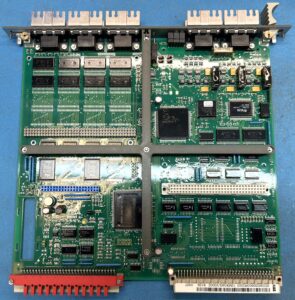

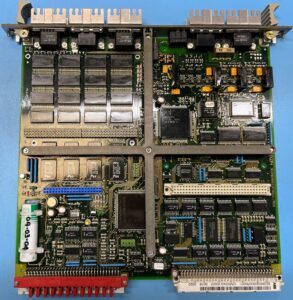

Vehicle Control Units (VCUs) are central to the safe and efficient operation of modern trains, serving as the primary controller for critical onboard systems. As these units age, the risk of failure due to component degradation increases, leading to higher maintenance costs and operational disruption.

eTrac Ltd has developed a structured VCU overhaul programme to address these challenges by renewing components known to affect long-term reliability. This case study highlights the technical scope and project execution for the Class 377 and Class 379 fleets, conducted in close partnership with Alstom, and GTR.

Scope of Work

The overhaul process targets components commonly associated with age-related degradation and known failure patterns.

Standard Renewals

- Electrolytic Capacitors – Replaced to prevent leakage and ensure stability.

- Relays – Renewed to eliminate mechanical and electrical fatigue.

- Optocouplers & Line Transceivers – Upgraded for improved signal reliability.

- Batteries – Proactively replaced to mitigate power loss risks.

Targeted Component Upgrades

- Encapsulated DC Converters – Replaced due to high failure incidence.

- Operational Amplifiers (Power Supply) – Known to degrade under stress and replaced as standard.

These component choices are based on extensive hands-on repair experience with VCU and Gateway units, ensuring a high level of reliability improvement. We also support customer-specific requirements, offering targeted component substitution on request.

Collaborative Approach

This overhaul programme represents a collaborative effort between:

- eTrac – Delivering technical leadership, diagnostics, repair and reassembly.

- Alstom – Our customer and key interface for the programme’s planning and execution.

- GTR (Govia Thameslink Railway) – The end user, providing operational insights and support.

The integration of expertise from all stakeholders ensures the most efficient and effective service possible, balancing technical rigour with operational needs.

Engineering Process

- Visual Inspection and Functional Testing – Inspection is conducted to IPC-A-610 standards for electronic assembly quality. Testing is conducted to record any faults on receipt of the units.

- Component Replacement and Re-Assembly – According to the defined renewal strategy and any repair requirements.

- Functional and Climate Testing – Verifies the correct operation of all logic, power, and I/O systems.

- Report and Identification – Repair reports are compiled to include serial number, components replaced, details of any additional work, repair date, and sign off. Units are labelled for traceability.

A 12-month warranty is provided on all work performed under this scope.

Project Highlights

- Class 377 Fleet: 414 units currently being overhauled.

- Class 379 Fleet: Overhaul initiated in 2025 for 60 units.

These projects reinforce asset reliability and ensure continued safe operation of GTR’s rolling stock.

Customer Impact

The project delivers significant value to both Alstom and GTR by:

- Improving electronic system resilience

- Reducing in-service failures and related service delays

- Extending VCU service life without full unit replacement

- Streamlining maintenance planning and costs

Our ability to work seamlessly with customers and suppliers is a core strength that supports long-term operational excellence.

Conclusion

This VCU overhaul demonstrates eTrac’s capability to manage technically complex, high-volume projects through close collaboration and engineering excellence. By proactively addressing component-level risks and leveraging strong partnerships with Alstom, and GTR, we provide a dependable and scalable solution to modern rail reliability challenges.

Simon Lane, Engineering Manager GTR Project – “This project has been hailed as an example of collaboration, investigation and production resulting in positive results for all parties and the wider shareholders alike. Working together ETRAC, Alstom and the TOC have produced a comprehensive deep dive into failure data and repair reports to produce a scope of work all parties are aligned to. Etrac produced the working process and this has led to a successful workstream with improved reliability across the fleet, again appreciated across all shareholders. The success of this and other workstreams is the reason we remain with, work with and will stay with ETRAC for the future.”